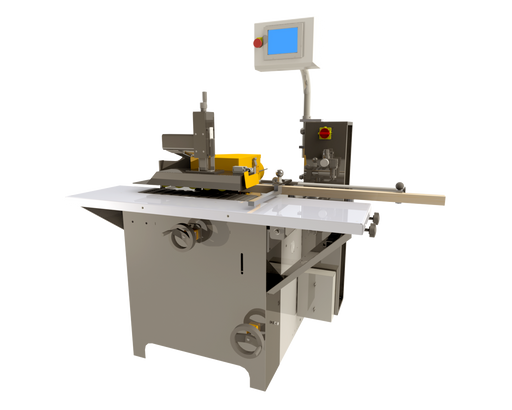

A shaper machine is a versatile woodworking tool used to shape and profile wood by removing material from the workpiece with a rotating cutter head. Unlike a router, which is handheld, a shaper is a stationary machine that allows for precise shaping and profiling of larger workpieces. Shaper machines are commonly used for creating decorative edges, molding, and raised panels, as well as for cutting joinery such as tenons and dovetails.

Key Features of Shaper Machines

Powerful Motor: Shaper machines are equipped with powerful motors to handle heavy-duty cutting tasks.

Variable Speed Control: Many shaper machines feature variable speed control, allowing for flexibility in cutting different materials and profiles.

Interchangeable Cutter Heads: Shapers can accommodate a variety of cutter heads, including straight, profiled, and molding heads, for versatility in shaping operations.

Adjustable Fence: An adjustable fence allows for precise positioning of the workpiece and customization of the shaping profile.

Dust Collection System: Integrated dust collection systems help keep the workspace clean and reduce airborne particles for improved safety and visibility.

Applications of Shaper Machines

Edge Profiling: Shaper machines are used to create decorative edges on furniture components, countertops, and architectural millwork.

Molding Production: Shapers are ideal for producing custom moldings, including baseboards, crown moldings, and door casings.

Joinery: Shapers can cut precise joinery such as tenons, dovetails, and rabbets, making them essential for cabinetmaking and furniture construction.

Panel Raising: Shaper machines are used to shape raised panels for cabinet doors and architectural details.

Choosing the Right Shaper

Power and Speed: Consider the power and speed capabilities of the shaper machine to ensure it can handle your desired cutting tasks efficiently.

Cutter Head Compatibility: Evaluate the compatibility of the shaper with different types of cutter heads to accommodate your shaping needs.

Fence Adjustability: Look for a shaper with a sturdy and adjustable fence for precise positioning and customization of shaping profiles.

Dust Collection: Choose a shaper with an effective dust collection system to maintain a clean and safe working environment.