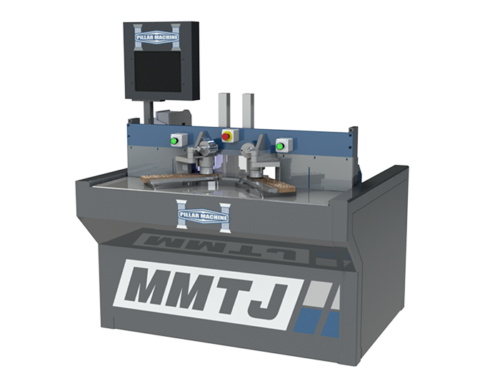

Pillar Machine | MMTJ – Miter Machine

Original price

$50,000.00

-

Original price

$50,000.00

Original price

$50,000.00

$50,000.00

-

$50,000.00

Current price

$50,000.00

The MMTJ is a full 3 Axis CNC machining center used for producing high quality miter joints used in cabinet door manufacturing. This machine produces between 175-200 doors per 8 hour shift with one operator.

The MMTJ performs the following functions:

- Mitering

- Mortising

- Tenoning

Standard Features:

- 3-Axis control for high quality joints and flexibility in machining various sizes of profiles. (X, Y and Z)

- 2 working zones

- 3 HP high frequency spindle for mortise (18,000 RPM)

- 6 HP high frequency spindle for tenon (18,000 RPM)

- 1″ x 3.5″ machining capability (larger sizes available upon request)

- 15″ industrial color touchscreen for creating and selecting programs

Advantages of The MMTJ:

- Elimination of complicated machine setups climb cut of both tenon and mortise cuts for a “tear out” free cut.

- The ability to cut MDF paper or vinyl wrapped profiles.

- Eliminates the need for applying inlays.

- Reduces the maintenance and cost associated with the tooling by more than 50% by eliminating end coping.

- Eliminates the need for outside profiling or sanding the edges of doors

- Eliminates the need for sanding the face of the doors

- Both stiles and rails are run face down for consistency of machining.

- Self aligning joints

- There is a more durable and aesthetically pleasing blind joint (no visible joint on edge of board)

- Multiple tool paths to choose from in tenon and miter (on the mortise side) to accommodate all profiles.

Options:

- Bar-code Reader

- Diamond tooling

- Pillar-Gauge CNC back fence (for use in sizing part lengths)

- Larger machining capabilities