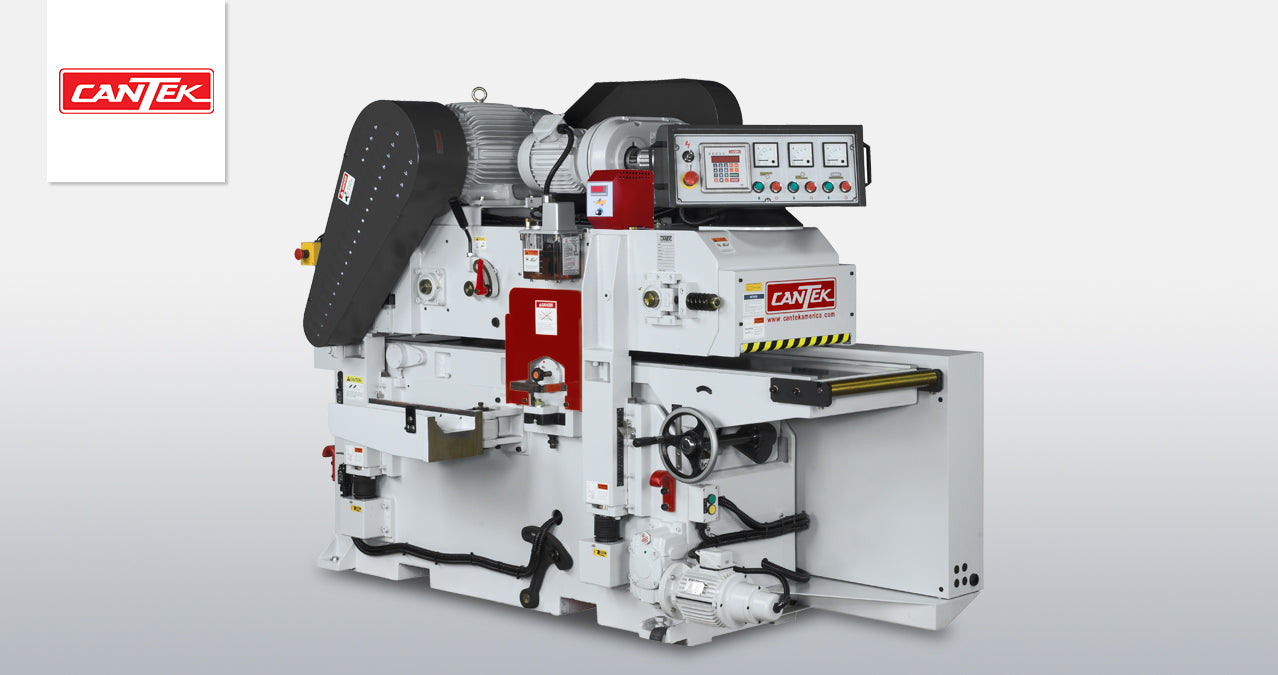

CANTEK | GT400BRD 16" X 6.7" Double Surfacer

Original price

$25,600.00

-

Original price

$25,600.00

Original price

$25,600.00

$25,600.00

-

$25,600.00

Current price

$25,600.00

Plane your material efficiently in a single pass.

The Cantek GT400BRD 16″ Double Surface Planer has a robust cast-iron body for industrial planing day in and day out. The spiral insert knife cutterheads produce a smooth planed finish with maximum stock removal. The material is passed over the bottom head with a spring-loaded pin feed system allowing it to act like a jointer to flatten the board prior to being planed to an accurate thickness with the top head

Why Cantek GT400BRD 16″ Double Surface Planer?

- Spring loaded conveyor pin system ensures material is passed over the bottom cutterhead to resulting in a flat and uniform board prior to planing to thickness on the top head

- Spiral insert knife cutterheads with two-sided solid carbide knives produce a smooth finish with increased stock removal capacity and extremely quiet operation

- Heavy-duty cast-iron machine body and table for vibration free cutting

- Digital electronic thickness adjustment in INCH and MM (Inch = 0.001” / mm = 0.01mm resolution) for precise thickness control

Key Advantages

- 16″ wide x 6.7″ thick planing capacity

- Cutterheads are spiral insert type with six (6) rows of carbide inserts

- (2) driven and (1) idle bed roll for superior feeding of even difficult material

- Swiveling control panel for more ergonomic access to machine controls

- Inverter variable speed control with feed speeds from 23 to 65 FPM

- Easy to access external handwheel adjustment of infeed bed

- Hard chromed worktable for high wear resistance

- Auto lubrication to conveyor chain, central lubrication for dovetail elevation guideways

- Section chipbreaker and sectional feed roller before top cutterhead

- Rubber outfeed top roller to prevent chip marking

- Over thickness safety shut-off bar across infeed.

- Ammeter for each motor on control panel to monitor motor load

Specifications

Maximum working width | 16″ | 405mm |

Maximum working thickness | 6.7″ | 170mm |

Minimum workpiece length | 10″ | 250mm |

Minimum working thickness | 0.315″ | 8mm |

Bottom jointing head motor | 10 HP | |

Top planing head motor | 15 HP | |

Feed motor | 2 HP | |

Table elevation motor | ½ HP | |

Cutterhead diameter | 4″ | 101mm |

Knife information | 30mmx12mmx1.5mm | 60 knives / head |

Cutterhead speed | 5000 RPM | |

Feed speed (variable) | 23~65 FPM | 8~24 m/min |

Dust collection | 2 @ 5″ diameter | 2 @ 125mm |

Table size | 19″ x 86″ | 482x2185mm |

Machine dimensions (LxWxH) | 86.6″ x 35.43″ x 66.93″ | 2200x900x1700mm |

Net weight | 4180 Lbs. | 1900 kgs |

Packaging dimensions | 90.5″ x 37.4″ x 72.83″ | 2350x1060x1940mm |

Gross weight | 4620 Lbs. | 2100 kgs |

Electrical Information | 460/3/60 = 33 amps | 230/3/60 = 66 amps | |