A rip saw is an essential woodworking machine designed for making longitudinal cuts, typically parallel to the grain of the wood. It excels in producing straight-line cuts that are crucial for creating consistent widths in boards and panels. The rip saw's primary function is to efficiently and precisely convert larger wood stock into narrower pieces. It is an indispensable tool for dimensioning, allowing woodworkers to obtain uniform-sized materials for various projects. Whether it's producing boards for cabinetry, flooring, or furniture, the rip saw's capacity to make parallel rip cuts makes it invaluable in the woodworking industry.

What's the Difference between Gang Rip Saws and Straight Line Rip Saws

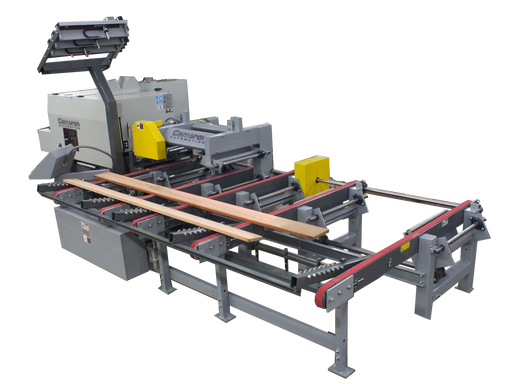

Gang Rip Saw:

A gang rip saw is designed for high-volume, large-scale production. It features multiple blades, often mounted closely together on a single arbor, allowing it to cut multiple pieces of material simultaneously in a single pass. This makes it exceptionally efficient for ripping large quantities of lumber quickly. Gang rip saws are commonly used in sawmills and manufacturing facilities where speed and volume are a priority.

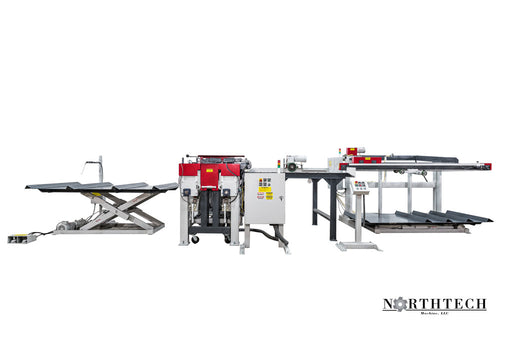

Straight Line Rip Saw:

A straight line rip saw, on the other hand, is engineered for precision and accuracy. It features a single, high-quality blade that ensures a perfectly straight and parallel cut along the length of a workpiece. This precision is essential for creating boards, panels, or strips with consistent widths, making it a valuable tool in industries such as cabinet making, flooring production, and furniture manufacturing.

Key Features of Rip Saws:

Rip saws offer several features that enhance their functionality:

- Adjustable Fence: An adjustable rip fence ensures straight and precise cuts at the desired width.

- Feed System: A smooth feed system moves the workpiece through the machine consistently, contributing to accurate results.

- Blade Configuration: Rip saws accommodate different blade types and sizes, allowing versatility in the type of cuts they can make.

- Safety Measures: Many models come with safety features like blade guards and emergency shut-off switches to protect operators.

Applications of Rip Saws:

Rip saws find applications across various woodworking sectors:

- Cabinet Making: In the production of cabinets and furniture, rip saws are used to create boards and panels of consistent dimensions.

- Flooring Production: They are crucial for making the straight-line cuts necessary for flooring materials, ensuring uniformity in each piece.

- Lumber Processing: Sawmills and wood processing facilities rely on rip saws to convert larger logs into smaller, manageable boards.

Benefits of Using Rip Saws:

The advantages of incorporating rip saws into woodworking operations are substantial:

- Precision: Rip saws produce straight-line cuts with exceptional accuracy, reducing the need for additional processing.

- Efficiency: They significantly expedite the dimensioning process, saving time and labor in preparing materials.

- Material Optimization: These machines help minimize waste, as they can efficiently convert larger stock into smaller pieces.

- Versatility: Rip saws can handle a variety of wood types, making them adaptable to different projects.

Choosing the Right Rip Saw:

Selecting the appropriate rip saw depends on specific needs:

- Rip Capacity: Ensure the machine's rip capacity accommodates the width of the materials you commonly work with.

- Blade Type: Consider the type and size of the blade for the specific cuts you need.

- Safety Features: Evaluate the machine's safety measures and ensure they align with your safety standards.

In conclusion, rip saws are fundamental tools for woodworking, facilitating the precise conversion of larger stock into smaller, uniform pieces. Their key features, applications, and benefits make them essential in sectors such as cabinet making, flooring production, and lumber processing. When choosing the right rip saw, woodworkers should consider rip capacity, blade type, and safety features to optimize their woodworking processes, reduce waste, and enhance efficiency in producing high-quality materials for various projects.