PivotLine Quick Start Kit: 6x6x6 U-Shape Ceiling Mount

The PivotLine System can be configured to fit any shop size and budget. Our quick-start kits cover some of our most popular use cases, and as your shop’s volume increases, the system can easily be expanded or reconfigured.

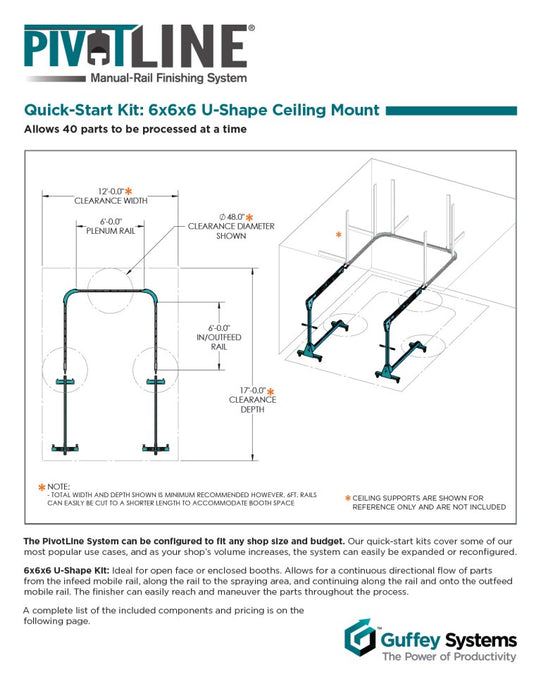

6x6x6 U-Shape Kit Overview

Ideal for open face or enclosed booths. Allows for a continuous directional flow of parts from the infeed mobile rail, along the rail to the spraying area, and continuing along the rail and onto the outfeed mobile rail. The finisher can easily reach and maneuver the parts throughout the process.

- Allows 40 parts to be processed at a time

- Plenum rail length: 6'-0"

- Clearance width: 12'-0"

- Clearance depth: 17'-0"

- Clearance diameter shown: 48.0"

- Infeed/Outfeed rail length: 6'-0"

Note: Total width and depth shown is minimum recommended. 6ft rails can easily be cut to a shorter length to accommodate booth space. Ceiling supports are shown for reference only and are not included.

Pricing Summary

- Subtotal: $10,274.00

- Shipping & handling: $0.00

- Discount: $0.00

- Tax: $0.00

- Total: $10,274.00

Included Components

| Description | Qty | Rate | Amount |

|---|---|---|---|

| Rolling Spray Hub Rolls smoothly and pivots in 90° increments allowing for easy spraying of all sides |

20 | $84.00 | $1,680.00 |

| Twist Stop Insert into stationary and mobile rails to prevent unwanted movement of materials |

4 | $89.00 | $356.00 |

| T-Bar — Short (17") Hang doors using... |

– | – | – |

Specifications

What is the Guffey Systems PivotLine Quick-Start Kit: 6x6x6 U-Shape Ceiling Mount?

The Guffey Systems PivotLine Quick-Start Kit: 6x6x6 U-Shape Ceiling Mount is an overhead-mounted paint and finish room conveyor system designed to optimize storage, mobility, and drying flow of sprayed cabinet doors, panels, and components within a compact U-shaped layout.

What does the 6x6x6 U-shape ceiling configuration mean?

The 6x6x6 configuration consists of three connected 6-foot overhead track sections forming a U-shaped conveyor path, allowing finished parts to circulate efficiently above the floor within a defined finishing space.

What is the primary purpose of a U-shape PivotLine system in a finish room?

The U-shape design creates a compact overhead loop for staging, flash-off, and drying, increasing part density while maintaining organized workflow.

How does the ceiling-mounted U-shape improve paint room efficiency?

By suspending parts overhead, the system frees floor space, reduces congestion, and enables continuous movement from spray application to drying.

What types of components can be stored on this system?

The PivotLine is designed for cabinet doors, drawer fronts, panels, face frames, moldings, and other sprayed components that require controlled drying and staging.

How does the U-shape layout maximize part density?

The U-shaped track allows more components to be staged in a compact footprint, making it ideal for high-volume cabinet finishing operations.

How does the ceiling-mounted version differ from the floor-mounted U-shape system?

The ceiling-mounted configuration keeps all parts elevated, eliminating floor interference and allowing full use of the finish room floor for operators and spray equipment.

How does the PivotLine reduce damage to freshly sprayed parts?

By minimizing manual handling and keeping parts suspended on controlled fixtures, the system reduces smudging, dents, and surface defects.

Is the 6x6x6 U-shape ceiling system suitable for production cabinet shops?

Yes, it is engineered for professional finishing operations that require organized, repeatable part flow through spray and drying stages.

Can the U-shape system function as a drying loop?

Yes, the continuous U-shaped path allows parts to circulate and remain suspended during flash-off and cure times.

What is included in the Quick-Start Kit?

The kit includes overhead track sections, corner transition components, mounting hardware, and core conveyor elements required to establish the U-shaped finish room system.

Does the ceiling-mounted system require structural support?

Yes, proper structural ceiling support is required to ensure safe load-bearing capacity for suspended sprayed components.

How does the PivotLine compare to traditional drying racks?

Unlike stationary racks, the PivotLine provides continuous overhead movement and organized sequencing of parts while reducing floor clutter.

Can this system integrate with spray booths?

Yes, the U-shape configuration can be positioned adjacent to spray booths or flash-off areas to create a seamless finishing workflow.

Is the system compatible with waterborne and solvent-based finishes?

Yes, it supports parts finished with waterborne coatings, lacquers, conversion varnishes, and other professional cabinet finishing materials.

How does the PivotLine increase finishing throughput?

By reducing staging bottlenecks and improving part mobility, the system allows spray operators to maintain steady production without delays.

Does the U-shape layout improve job organization?

Yes, the defined conveyor path keeps parts organized in sequence, improving batch tracking and reducing mix-ups between jobs.

Can the 6x6x6 U-shape ceiling system be expanded?

Yes, the modular overhead design allows additional sections or layout changes as finishing capacity increases.

Is this configuration suitable for smaller paint rooms?

Yes, the compact U-shape ceiling layout is especially beneficial in small to mid-size cabinet shops that need to maximize vertical space.

Who should choose the Guffey Systems PivotLine 6x6x6 U-Shape Ceiling Mount?

This system is ideal for professional cabinet finishing operations seeking increased part density, improved workflow control, reduced handling damage, and optimized use of vertical space in paint and finish rooms.