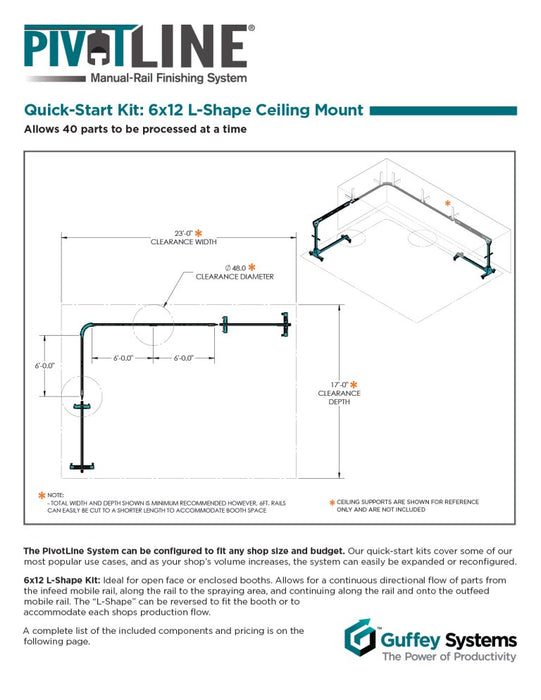

PivotLine Quick-Start Kit: 6x12 L-Shape Ceiling Mount

Allows 40 parts to be processed at a time

The PivotLine System can be configured to fit any shop size and budget. Our quick-start kits cover some of our most popular use cases, and as your shop's volume increases, the system can easily be expanded or reconfigured.

6x12 L-Shape Kit: Ideal for open face or enclosed booths. Allows for a continuous directional flow of parts from the infeed mobile rail, along the rail to the spraying area, and continuing along the rail and onto the outfeed mobile rail. The "L-Shape" can be reversed to fit the booth or to accommodate each shop's production flow.

Guffey Systems

The Power of Productivity

| Description | Qty | Rate | Amt |

|---|---|---|---|

| PivotLine Stationary Rail Kit 6x12 L-Shape Complete | 1 | $2,343.00 | $2,343.00 |

| Mobile Rail | 2 | $2,150.00 | $4,300.00 |

| Rolling Spray Hub | 20 | $84.00 | $1,680.00 |

| Twist Stop | 4 | $89.00 | $356.00 |

| T-Bar - Short (17") | 6 | $25.00 | $150.00 |

| T-Bar - Medium (34") | 8 | $42.00 | $336.00 |

| T-Bar - Large (46") | 6 | $56.00 | $336.00 |

| Offset Hanger w/screws | 20 | $112.00 | $2,240.00 |

| Universal Hanger w/screws | 10 | $112.00 | $1,120.00 |

| EFC (Spring Clip) | 60 | $15.00 | $900.00 |

| Subtotal | $9,927.00 | ||

| Shipping & Handling | $0.00 | ||

| Discount | $0.00 | ||

| Tax | $0.00 | ||

| Total | $9,927.00 | ||

* 6ft rails can easily be cut to shorter length if needed

Specifications

What is the Guffey Systems PivotLine Quick-Start Kit: 6x12 L-Shape Ceiling Mount?

The Guffey Systems PivotLine Quick-Start Kit: 6x12 L-Shape Ceiling Mount is an overhead-mounted paint and finish room conveyor system designed to improve storage, mobility, and workflow of sprayed cabinet doors, panels, and components in finishing environments.

What is the primary purpose of the PivotLine system in a paint room?

The PivotLine system is engineered to streamline the movement, staging, drying, and storage of freshly sprayed parts, reducing handling damage and increasing finishing throughput.

What does the 6x12 L-Shape configuration mean?

The 6-foot by 12-foot L-shaped ceiling configuration creates a 90-degree overhead conveyor path, allowing finished parts to move around corners within a spray booth, flash area, or drying zone.

How does the PivotLine improve finish room efficiency?

By suspending parts overhead, the system frees floor space, reduces bottlenecks, and allows continuous part flow between spray, flash, and dry stages.

What types of parts can be stored on the PivotLine system?

The system is designed for cabinet doors, drawer fronts, panels, moldings, face frames, and other sprayed components commonly processed in professional finishing rooms.

Is the PivotLine designed specifically for finishing environments?

Yes, Guffey Systems products are engineered for paint and finishing rooms where mobility, space optimization, and protection of freshly sprayed surfaces are critical.

How does the ceiling-mounted configuration benefit a spray booth layout?

The ceiling-mounted track keeps parts elevated and protected, maximizing usable floor space for operators and spray equipment.

Does the L-shape configuration help in tight finishing rooms?

Yes, the 90-degree layout allows parts to move around corners, making it ideal for compact paint rooms or segmented spray and drying zones.

How does the PivotLine reduce damage to freshly sprayed parts?

By minimizing manual handling and keeping parts suspended on controlled fixtures, the system reduces smudging, dents, and surface defects.

Can the 6x12 L-Shape PivotLine support high-volume cabinet finishing?

Yes, it is designed for production environments where consistent part flow and organized staging are necessary for maintaining output.

What is included in the Quick-Start Kit?

The kit includes overhead track sections, corner transition hardware, mounting brackets, and core conveyor components required to establish a functional L-shaped finish room system.

Does the system require structural ceiling support?

Yes, proper structural support is required for overhead installation to ensure safe load-bearing capacity for suspended parts.

How does the PivotLine compare to floor drying racks?

Unlike floor racks, the PivotLine keeps parts elevated, reduces floor congestion, and allows continuous movement rather than stationary storage.

Can the system integrate with finishing racks and fixtures?

Yes, Guffey Systems products are designed to work with specialized hanging fixtures and racks optimized for sprayed component storage.

Is the PivotLine suitable for waterborne and solvent-based finishing processes?

Yes, the system supports parts finished with waterborne coatings, lacquers, conversion varnishes, and other common cabinet finishing materials.

How does the PivotLine help increase finishing throughput?

By improving part mobility and reducing handling delays, the system allows spray operators to maintain continuous production without workflow interruptions.

Does the system improve organization in a finish room?

Yes, the defined conveyor path keeps parts organized in sequence, reducing confusion and improving batch control.

Can the 6x12 L-Shape system be expanded later?

Yes, the modular design allows additional track sections or configuration changes as finishing capacity grows.

Is the PivotLine appropriate for small cabinet shops?

Yes, the 6x12 configuration is especially useful for small to mid-size cabinet shops seeking to improve finishing efficiency without expanding floor space.

Who should choose the Guffey Systems PivotLine 6x12 L-Shape Ceiling Mount?

This system is ideal for professional cabinet finishing operations that need improved mobility, better part protection, organized drying flow, and optimized paint room efficiency.