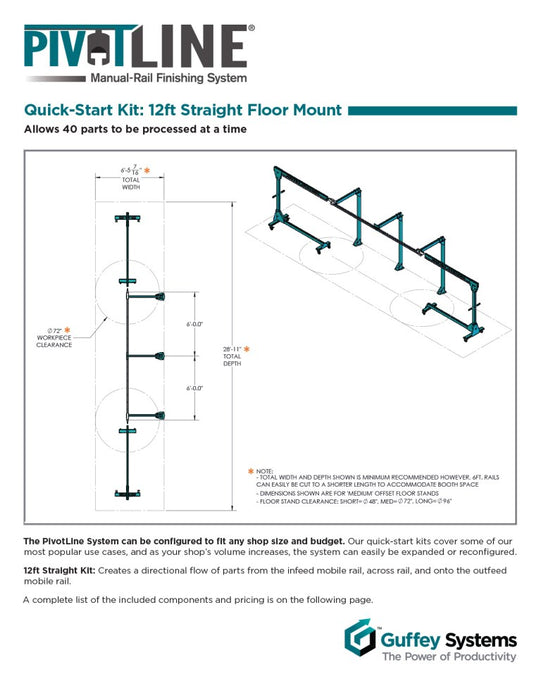

PivotLine Quick-Start Kit: 12ft Straight Floor Mount

Allows 40 parts to be processed at a time

The PivotLine System can be configured to fit any shop size and budget. Our quick-start kits cover some of our most popular use cases, and as your shop's volume increases, the system can easily be expanded or reconfigured.

12ft Straight Kit: Creates a directional flow of parts from the infeed mobile rail, across rail, and onto the outfeed mobile rail.

Guffey Systems

The Power of Productivity

| Description | Qty | Rate | Amt |

|---|---|---|---|

| PivotLine Stationary Rail Kit 12ft. Straight Complete | 1 | $1,558.00 | $1,558.00 |

| Mobile Rail | 2 | $2,150.00 | $4,300.00 |

| Rolling Spray Hub | 20 | $84.00 | $1,680.00 |

| Twist Stop | 4 | $89.00 | $356.00 |

| T-Bar - Short (17") | 6 | $25.00 | $150.00 |

| T-Bar - Medium (34") | 8 | $42.00 | $336.00 |

| T-Bar - Large (46") | 6 | $56.00 | $336.00 |

| Offset Hanger w/screws | 20 | $112.00 | $2,240.00 |

| Universal Hanger w/screws | 10 | $112.00 | $1,120.00 |

| EFC (Spring Clip) | 60 | $15.00 | $900.00 |

| Floor Stand - Comes with 1 of 3 optional stand-off arm sizes | 3 | $615.00 | $1,845.00 |

| Subtotal | $10,987.00 | ||

| Shipping & Handling | $0.00 | ||

| Discount | $0.00 | ||

| Tax | $0.00 | ||

| Total | $10,987.00 | ||

* 6ft rails can easily be cut to shorter length if needed

Specifications

What is the Guffey Systems PivotLine Quick-Start Kit: 12ft Straight Floor Mount?

The Guffey Systems PivotLine Quick-Start Kit: 12ft Straight Floor Mount is a modular floor-mounted panel handling and pivot system designed to safely move, rotate, and stage large sheet goods in cabinet shops and production environments.

What is the primary purpose of the PivotLine system?

The PivotLine system reduces manual lifting, improves ergonomic panel handling, and increases workflow efficiency by providing guided pivoting and controlled movement along a fixed straight track.

What does the 12ft Straight Floor Mount configuration mean?

The 12-foot straight configuration provides a linear, floor-anchored handling track that allows panels to travel and pivot along a defined straight path within a compact shop footprint.

How is the 12ft version different from the 18ft configuration?

The 12ft system is ideal for smaller work cells or tighter layouts, offering the same controlled handling benefits while occupying less linear floor space than the 18ft configuration.

What types of materials can be handled with the PivotLine system?

The system is designed to support plywood, MDF, particleboard, laminated panels, solid surface materials, and other sheet goods commonly used in cabinetry and millwork production.

How does the PivotLine improve shop safety?

By minimizing manual lifting and awkward repositioning, the system helps reduce strain injuries and accidental panel drops while maintaining stable, guided movement.

Is the PivotLine 12ft system suitable for cabinet production environments?

Yes, the 12ft configuration is well suited for cabinet shops that require repetitive panel rotation and staging within a defined work area.

What is included in the PivotLine Quick-Start Kit?

The Quick-Start Kit includes the necessary floor-mounted track sections, pivot hardware, and structural components required to establish a functional 12-foot straight handling line.

Can the 12ft PivotLine system be expanded in the future?

Yes, the modular design allows additional track sections or reconfiguration as shop workflow and production demands evolve.

Is the 12ft Straight Floor Mount suitable for high-volume production?

Yes, it is designed to support repetitive material handling tasks in professional cabinet and millwork production environments.

What type of shop layout benefits most from the 12ft straight configuration?

Compact production cells, CNC loading zones, assembly areas, and edgebander staging stations benefit from the controlled, linear material flow of the 12ft system.

Does the floor-mounted system require special installation?

The system must be properly anchored to a stable concrete floor according to installation guidelines to ensure safe and reliable operation.

How does the PivotLine compare to panel carts?

Unlike manual carts, the PivotLine provides guided movement and pivot functionality, improving efficiency, reducing labor strain, and enhancing consistency.

Can the 12ft PivotLine integrate with CNC routers?

Yes, it can be positioned near CNC routers to streamline loading, unloading, and staging of processed panels.

How does the system reduce panel damage?

The controlled pivot mechanism and guided track reduce accidental drops, edge impacts, and surface scratching during material handling.

What are the labor efficiency benefits of the 12ft PivotLine?

The system reduces the number of employees required to safely move large panels and improves ergonomic positioning, increasing overall throughput.

Is the PivotLine suitable for handling assembled cabinet components?

Depending on configuration and load specifications, the system can assist in handling large panels and certain assembled components within safe operating limits.

Can the PivotLine be relocated if the shop layout changes?

Yes, the modular floor-mounted design allows reconfiguration or relocation as production needs change.

How does the PivotLine improve workflow consistency?

By providing a defined travel path and controlled pivoting action, the system standardizes panel movement and reduces workflow variability.

Who should choose the Guffey Systems PivotLine 12ft Straight Floor Mount?

This configuration is ideal for cabinet and millwork operations seeking safer panel handling, improved ergonomic efficiency, and a compact material flow solution within smaller or segmented production layouts.