Leadermac | Smartmac Moulder Series

by Leadermac

Original price

$50,000.00

-

Original price

$50,000.00

Original price

$50,000.00

$50,000.00

-

$50,000.00

Current price

$50,000.00

Why Leadermac Smartmac Moulder Series?

- Industrial moulder design with a solid cast iron frame produces unparalleled finished part quality in its class.

- Never has a moulder with such an industrial design and a wide range of features been available at this price point.

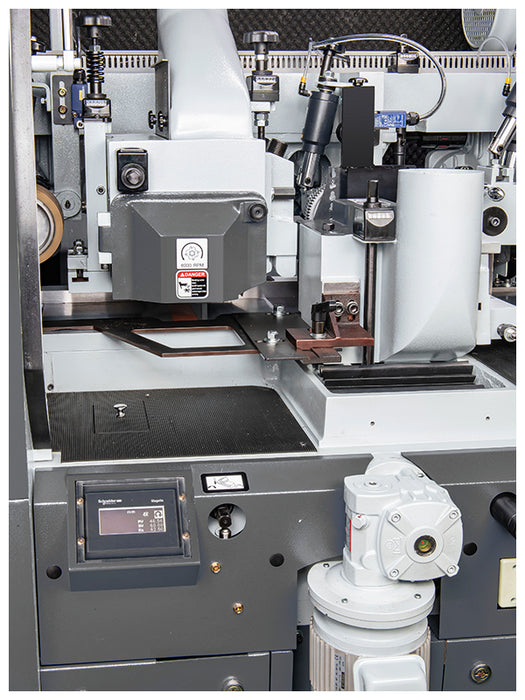

- Compact design ensures it can fit in almost any shop.

- Turnkey solutions include on-site operator and maintenance training.

Key Advantages

- Heavy-duty cast iron frame provides superior vibration damping, which produces superiorly finished parts and promotes long bearing & machine life.

- Small footprint allows the Smartmac to fit into nearly any shop.

- All tables and fences hard chromed with approximately 0.012″-0014″ thick hard chrome, which ensures maximum longevity.

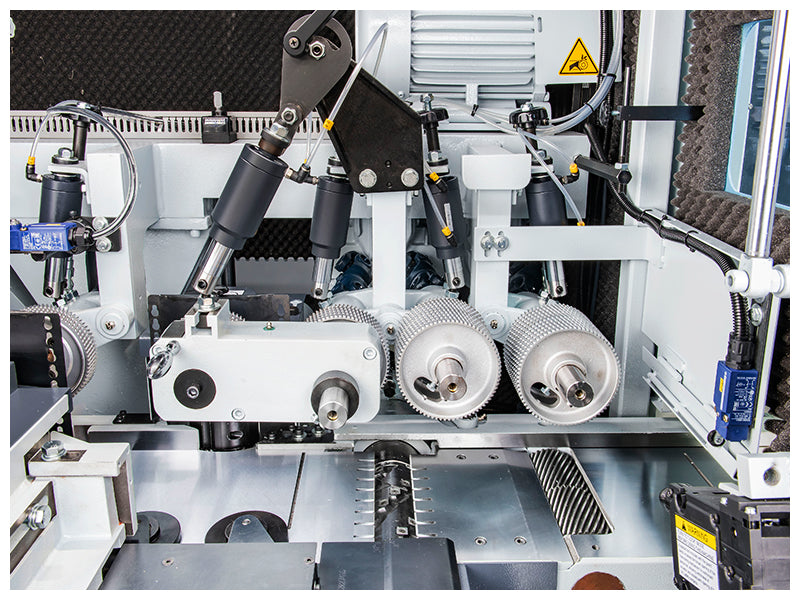

- Comes with more top-driven and bottom full-width driven feed rolls than other moulders of its size.

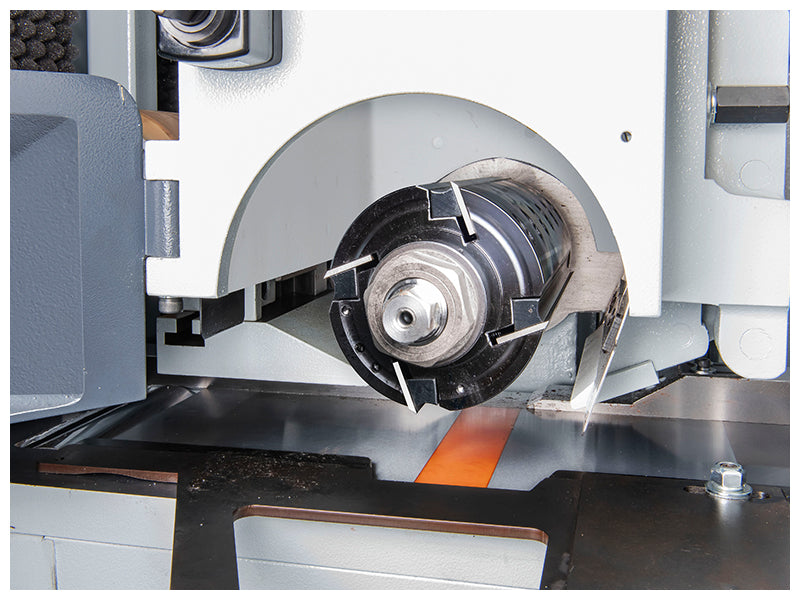

- 6000 RPM spindles each with (4) ABEC 6 precision bearings per spindle which provides smooth surface finish results.

- Side heads share a motor allowing the machine length to be shortened.

- Pneumatic side holdover provides consistent side pressure to the fence.

- Pneumatic hold down pressure to all top feed rolls provides consistent and repeatable pressure.

- Pneumatic chip breakers ensuring consistent pressure.

- Full width driven infeed & outfeed bed rolls.

- Dual SIKO quick set counters to assist in quick and accurate changeovers.

- Axial adjustment of last bottom head from front of machine.

- Table lubrication system.

- Centralized grease lubrication system.

- Safety sound enclosure is standard.

- Pneumatic pressure to chip breakers, holdovers, and top feed rolls.

Specifications

Working widths | 0.6″ to 7″ or 9″ |

Working thickness | 0.25″ to 5″ |

Number of spindles | 1 to 5 |

Spindle RPM | 6000 RPM (7200 opt) |

Standard feed speed | 20 to 80 FPM |

Minimum part length | 8″ (butt to butt) |

Axial adjustment of vertical spindles | 0.8″ (standard) |

Axial adjustment of horizontal spindles | 0.8″ (standard) |

Infeed bed length | 78″ (2m), 98″ (2m) or 120″ (2.5m) |