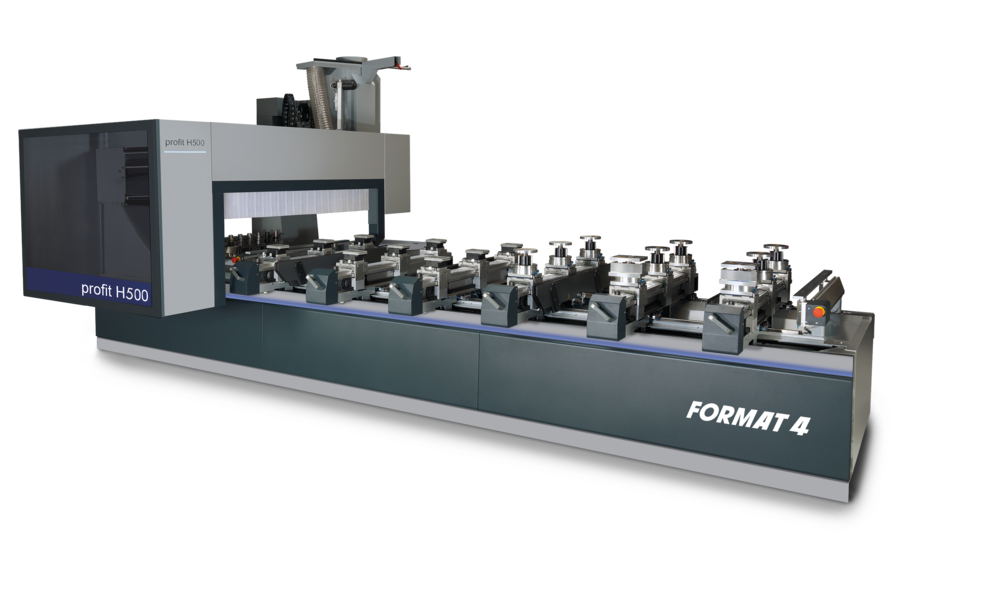

Format4 | profit H500R 5-Axes CNC Machine Center

5-Axis CNC Precision with Limitless Creativity

One machine, five axes, limitless creativity It is universal workshops in particular, where the individual processing of various materials is becoming increasingly important. The most up-to-date 5 axes CNC technology guarantees limitless creativity, and at the same time reduces the initial investment cost and subsequent costs for special aggregates and tools. Individual tooling configuration and fully automatic production at a manageable investment level – the Format4 profit H500R makes the future of component manufacturing profitable. The high performance main spindle warranty excellent results at every angle regardless of the material. In conjunction with the 18 independent drilling spindles and integrated grooving saw aggregate, the profit H500R offers limitless processing possibilities and ensures shortest possible production cycles. In the new, completely reengineered design, the CNC machining centres from Format4 display dynamics, power and high end technology from the first glance. Hose-free Format4 dual circuit system with vacuum pod height of 100 mm 2 CNC controlled Z-axes for the shortest of production cycles s-motion: Automatic console and vacuum pod positioning

- One machine, five axes, limitless creativity

- It is universal workshops in particular, where the individual processing of various materials is becoming increasingly important

- The most up-to-date 5 axes CNC technology guarantees limitless creativity, and at the same time reduces the initial investment cost and subsequent costs for special aggregates and tools

- Individual tooling configuration and fully automatic production at a manageable investment level

- The Format4 profit H500R makes the future of component manufacturing profitable

- The high performance main spindle warranty excellent results at every angle regardless of the material

- In conjunction with the 18 independent drilling spindles and integrated grooving saw aggregate, the profit H500R offers limitless processing possibilities and ensures shortest possible production cycles

- In the new, completely reengineered design, the CNC machining centres from Format4 display dynamics, power and high end technology from the first glance

- Hose-free Format4 dual circuit system with vacuum pod height of 100 mm

- 2 CNC controlled Z-axes for the shortest of production cycles

- s-motion: Automatic console and vacuum pod positioning

Key Features

Highlights

- Advanced 5-Axis Technology: Equipped with the latest 5-axis CNC technology, the profit H500R enables limitless creativity by processing materials at any angle, reducing the need for specialized tools and lowering investment costs, making it ideal for universal workshops.

- High-Performance Main Spindle: Features a powerful 5-axis spindle with a 12 kW or optional 15 kW motor, supported by liquid cooling and ceramic bearings, ensuring durable precision and smoothness up to 24,000 rpm, delivering excellent results across diverse materials.

- Automatic Console and Vacuum Pod Positioning (s-motion): Utilizes fully automatic "s-motion" consoles for rapid and high-quality processing of door and window components, eliminating manual setup and enhancing productivity with precise positioning.

Details

- 18-Spindle Drill Head with Grooving Saw: Includes 12 vertical drilling spindles (32 mm spacing, individually controllable), 6 horizontal drilling spindles (4 in X-axis, 2 in Y-axis, 32 mm spacing), and an integrated slot cutter in the X-axis. The inverter-driven motor reaches up to 7,500 rpm, covering the entire working field for vertical and horizontal drilling with exceptional flexibility.

- Two CNC-Controlled Z-Axes: The aggregate carrier with a 500 mm Z-axis travel allows quick alternation between the boring unit and main spindle, accommodating longer tools for processing higher workpieces, reducing production cycles significantly.

- Hose-Free Dual Circuit System: Features a vacuum pod height of 100 mm, ensuring efficient dust and chip management without hoses, enhancing workspace cleanliness and safety while supporting the machine’s dynamic design.

- Rotary Tool Changer with 24 Positions: Mounted at the back of the outrigger, this changer moves along the X-axis, minimizing tooling changeover times and boosting productivity. A 12-position linear tool changer offers additional space for routing tools, protected by a cover against dust and chips.

- High-Quality Guiding Systems: The X-axis uses recirculating ball bearings on hardened and polished linear guides with a cambered rack and pinion gear, while the Y- and Z-axes employ polished recirculating ball spindles. Automatic lubrication, time-controlled and pneumatically engaged, ensures low-maintenance reliability.

- Chip Transporter and Extraction Hood: Includes a chip transporter on the left side for manual removal, keeping the workshop clean. The extraction hood adjusts automatically to workpiece height, reducing dust and noise emissions for a safer working environment.

- lightPos LED Positioning System: Uses over 6,000 LEDs to visually indicate suction cup size, position, orientation, and console positions with millimeter precision. A sophisticated color management system (RGB LEDs on X-axis for status) enhances setup accuracy, especially in alternating operations.

- F4®Integrate Software and Touch-Screen Control: Offers a state-of-the-art interface with a tool library (F4Toolbox), programming section (F4Create with CAD), and machine control (F4Operate) on one screen. Based on G-Code, it supports external programs, with an intuitive touch-screen for maximum user-friendliness.

- Automatic Tool Length Measuring: Determines tool length with one-hundredth millimeter accuracy within the machine, eliminating operator errors and ensuring precise machining.

- Customizable Console Table and Stops: Equipped with rear and center fence rows (front row optional), featuring solid cylinder stops for flexible referencing of small to large workpieces. Optional configurations include 6 or 8 consoles with varying automation levels.

- Safety and Ergonomics: Offers multiple safety concepts (light barrier, foot mat, bumper, or combinations) and a foot switch bar along the working area, eliminating the need to search for pedals, blending seamlessly into the machine’s design.

- Attachments and Accessories: Includes optional maintenance openings, a 3D simulator for machining time calculation and collision checks, and status-indicating lighting. Web context suggests compatibility with advanced aggregates (e.g., 5-motion unit, chip deflectors), reflecting Format4’s modular approach, though not detailed here.

- Durability and Precision: Built with solid design and premium Austrian components, the profit H500R ensures uncompromised productivity, supported by a perfect service package, automation solutions, and networked workshop capabilities.

Technical Specifications

| Category | Details |

|---|---|

| Machining Unit |

|

| General |

|