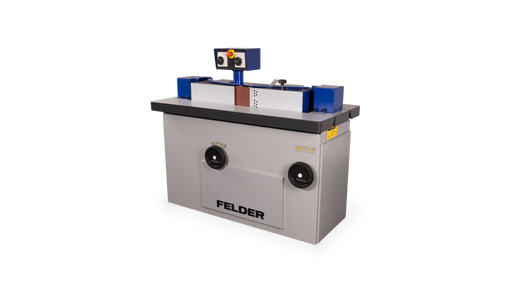

An edge sander, also known as an oscillating brush sander, is a woodworking machine used to sand and finish the edges of wooden workpieces. Its primary function is to smooth rough edges, refine contours, and remove imperfections, providing a uniform and consistent finish along the edges of boards, panels, or profiles.

Key Features of an Edge Sander

Oscillating Sanding Belt: Edge sanders feature a sanding belt that oscillates or moves back and forth, ensuring even sanding and preventing gouging or burning of the workpiece.

Adjustable Sanding Table: Many machines come with adjustable sanding tables or platens to accommodate different workpiece thicknesses and angles, allowing for precise sanding of various edge profiles.

Variable Speed Control: Some edge sanders offer variable speed control features, allowing operators to adjust the sanding belt speed to match the material type and desired finish quality.

Dust Collection System: Certain models feature integrated dust collection systems or ports to capture sanding dust and debris, maintaining a clean and safe working environment and improving sanding efficiency.

Tilt and Angle Adjustment: Edge sanders may come with tilt and angle adjustment mechanisms to sand beveled edges or chamfered profiles accurately, providing versatility for a wide range of woodworking applications.

Applications of Edge Sanders

Cabinetmaking: Edge sanders are commonly used in cabinet shops and woodworking factories to sand the edges of cabinet doors, drawer fronts, and furniture components for a smooth and uniform finish.

Millwork and Joinery: Woodworkers utilize edge sanders to refine the edges of moldings, trim pieces, and architectural millwork components, ensuring precise fit and finish for installation.

Door and Window Production: Edge sanders are employed in door and window manufacturing facilities to sand the edges of door stiles, rails, and window frames, preparing them for painting, staining, or finishing.

Edge Profiling and Shaping: Woodshops use edge sanders to shape and profile the edges of tabletops, countertops, and panel components, creating custom edge profiles or easing sharp edges for safety and aesthetics.

Choosing the Right Edge Sander

Sanding Capacity: Consider the sanding capacity of the edge sander, including the width and thickness of the sanding belt, to ensure it can accommodate the size and type of workpieces you typically sand.

Adjustability and Versatility: Look for an edge sander with adjustable tables, sanding angles, and speed control features to meet the diverse sanding needs of your woodworking projects.

Dust Collection Efficiency: Evaluate the effectiveness of the dust collection system to ensure it can efficiently capture sanding dust and debris, keeping the work area clean and reducing airborne particulates.

Build Quality and Durability: Choose a machine with sturdy construction and durable components to withstand the rigors of daily use in a woodworking environment, ensuring longevity and reliable performance.