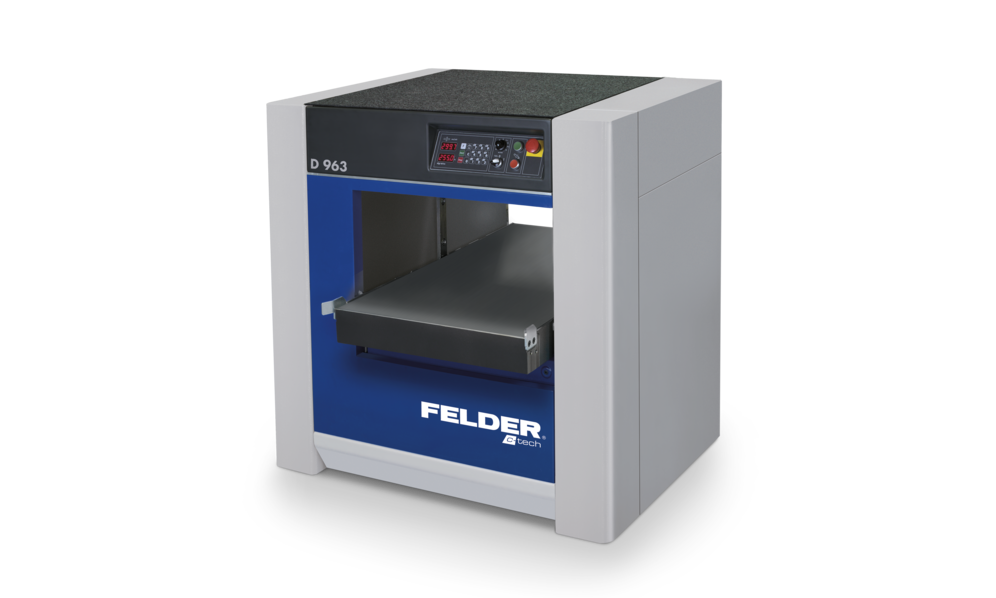

Felder | D 963 c-tech Planer

by Felder Group

Original price

$50,000.00

-

Original price

$50,000.00

Original price

$50,000.00

$50,000.00

-

$50,000.00

Current price

$50,000.00

The Felder D 963 Planer, including the D 963 c-tech variant, is the most heavy-duty planer in the Felder range, designed for maximum performance and precision with a 24 51/64" (630 mm) planing width. Featuring a solid thicknessing table, four trapezoidal threaded spindles, and the optional Silent-Power® spiral knife cutterblock, it ensures superb machining, durability, and precision for solid wood and plastic processing (c-tech). Its intuitive controls and heavy-duty components make it a powerhouse for professional woodworking.

Key Features

Highlights

- Variable Infeed: Adjustable feed speed (13–52 ft/min for D 963, 6–26 ft/min for c-tech) ensures optimal planing results for various wood types and grains.

- Digi-Drive: Programmable thicknessing table control with numeric keypad for precise, automatic positioning; includes LED displays for target and actual values, with incremental adjustments and 4 programmable positions.

Details

- Power-Drive: Fully electrical thicknessing table control for quick, precise height adjustments with fine-tuning via button and LED display for exact values.

- Silent-Power®: Spiral blade cutterblock reduces noise by 50%, provides tear-free planing, up to 20 times longer blade life, four cutting edges per knife, and optimized chip extraction for reduced chip volume (standard on c-tech, optional on D 963).

- Cutterblock Housing: Solid cast iron housing built for heavy-duty work, with optional rubberized outfeed rollers; pressure beams and rubber/segmented infeed rollers handle workpieces of varying widths.

- Felder System Cutterblock: 4 knife cutterblock with quick knife changes (under 2 minutes), self-aligning knives, no resin buildup, and smooth operation (standard on D 963).

- Perfect Planing Technology: Two pressure bars prevent fluttering, especially for thinner workpieces during thicknessing.

- Spring Loaded Segmented Pressure Beam: Prevents fluttering for thin workpieces or varying thicknesses, recommended with rubberised infeed roller.

- Application of Lubricants: Optional lubricant application via wick from tank to the workpiece underside for smoother processing.

- Trapezoidal Threaded Spindle: Four spindles ensure precision and high load-bearing capacity, with longitudinal guides absorbing feed pressure.

- Adjustable Under Table Roller: Optional rollers for processing resinous or moist workpieces.

- Scissor Lifting Table: Optional extension of thicknessing table by 45 9/32" for enhanced support.

- Table Extension: 22 7/16" long table extension with outfeed workpiece roller for simultaneous processing of multiple workpieces.

- Support Roller: Optional infeed roller and lubrication unit for processing wet or resinous wood.

Technical Specifications

| Category | Details (D 963 / D 963 c-tech) |

|---|---|

| Electrics |

|

| Cutterblock |

|

| Thicknesser and Feed Gears |

|

| General |

|

| Accessories |

|