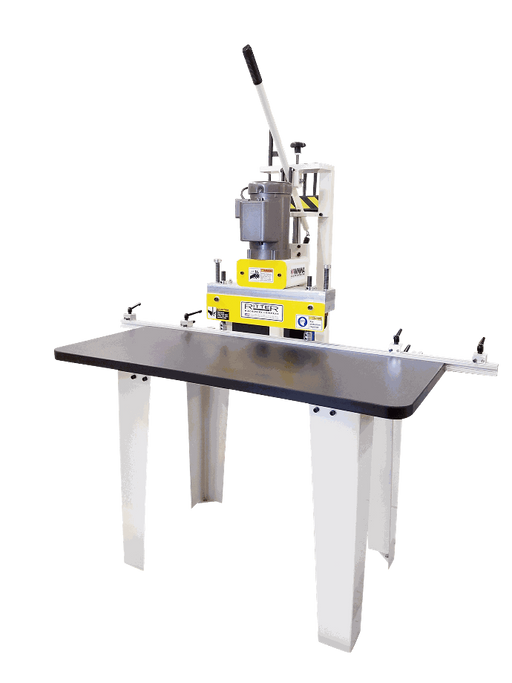

A line boring machine, also known as a single row line drill, is a precision machining tool used to bore multiple holes in a straight line along a horizontal or vertical axis. Its primary function is to accurately drill holes with consistent spacing and alignment, making it ideal for creating dowel joints, hinge mortises, and other precision bores in wood, metal, or plastic workpieces.

Key Features of a Line Boring Machine

Adjustable Spindle Speed: Line boring machines come with adjustable spindle speed settings to accommodate different materials and hole diameters, ensuring optimal drilling performance.

Multiple Spindle Configurations: Many machines offer multiple spindle configurations, allowing for simultaneous drilling of multiple holes to improve efficiency and productivity.

Precision Depth Control: Line boring machines feature precision depth control mechanisms to ensure consistent bore depths and uniform hole sizes, crucial for achieving accurate joinery and fittings.

Adjustable Fence and Stops: Some machines are equipped with adjustable fences and stops to facilitate precise positioning and alignment of workpieces, enabling repeatable drilling operations.

Integrated Dust Collection: Certain models come with built-in dust collection systems or ports to capture drilling debris and maintain a clean and safe working environment.

Applications of Line Boring Machines

Dowel Joint Assembly: Line boring machines are commonly used to create dowel joints for joining wood components in furniture making, cabinetmaking, and woodworking projects.

Hinge and Hardware Installation: Line boring machines are employed for drilling accurate holes for hinge mortises, shelf pins, and hardware fittings in cabinets, doors, and furniture pieces.

Custom Woodworking: Woodworkers utilize line boring machines for creating custom joinery, such as dadoes, grooves, and rabbets, in wood panels, shelves, and casework.

Metal Fabrication: Line boring machines are used in metalworking applications for drilling precision holes in metal components, such as engine blocks, cylinder heads, and chassis frames.

Choosing the Right Line Boring Machine

Number of Spindles: Consider the number and configuration of spindles to match the drilling requirements and production volume of your projects.

Spindle Adjustability: Look for machines with adjustable spindle spacing, depth control, and angle settings to accommodate various hole patterns and drilling angles.

Accuracy and Precision: Choose a line boring machine with robust construction, precise alignment mechanisms, and reliable depth control features to ensure accurate and repeatable drilling results.

Workpiece Size and Capacity: Evaluate the size and capacity of the machine's worktable or bed to accommodate the dimensions and weight of your workpieces.