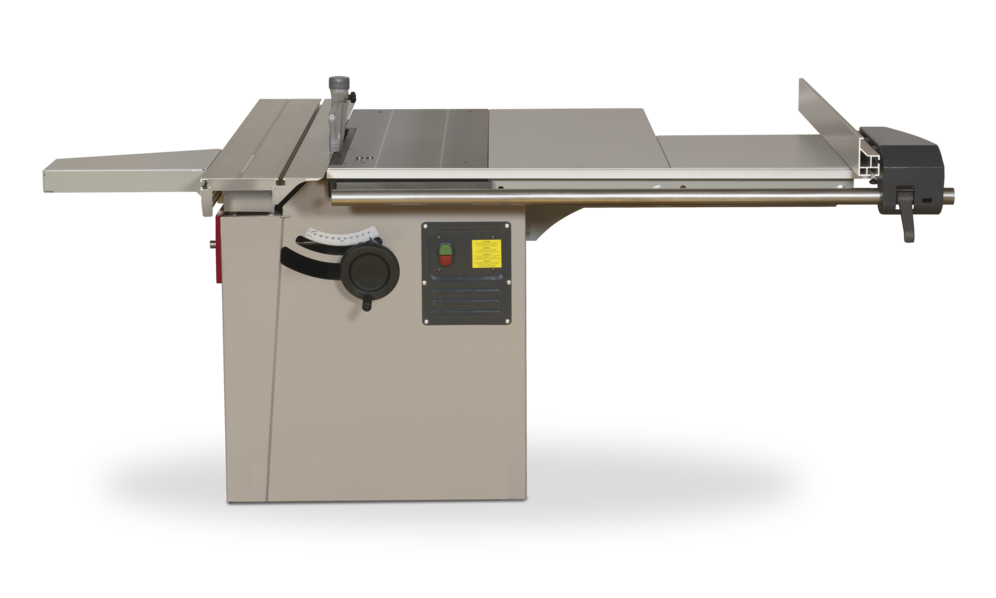

Hammer | K3 winner 48×48 Sliding Panel Table Saw

by Felder Group

Original price

$50,000.00

-

Original price

$50,000.00

Original price

$50,000.00

$50,000.00

-

$50,000.00

Current price

$50,000.00

The Hammer K3 Winner 48x48 Sliding Table Saw is a precision circular saw tailored for professional woodworkers, featuring a 48" sliding table and 49" rip capacity for enhanced versatility. Designed for solid wood, panel materials, plastics, and aluminum, it delivers exact rip, cross, and miter cuts with smooth operation, ensuring reliability and precision.

Key Features

- Decision Reliability for Many Years: Built with Austrian craftsmanship and strict quality standards for long-lasting performance.

- Strong Motors – Perfect Power Transmission: Large Poly-V belts and counter surface ensure near-perfect power transfer from the 4.0 HP motor to the saw arbor.

- Stable-Compact-Precise, the Hammer Saw Aggregate: Smooth, precise saw unit with 103 mm cutting height, 250–315 mm blade diameter, tiltable 90°–45° for accurate miter cuts.

- Grooving, Slot and Tenoning with the Saw: Supports dado tooling (8–19.5 mm) for grooves, tenons, and slots.

- The Industrial Rip Fence: Cast iron rip fence with micro-adjustment, adjustable up to 49" (1250 mm) on a round bar guide for smooth, precise operation.

- The Aluminium Sliding Table: 1250 mm (48") anodised sliding table with high-quality guiding system for maximum accuracy.

- Crosscut and Miter Cuts: 900 mm crosscut fence, adjustable +45° to -45°, with integrated scale and magnifying glass for precise settings.

- Table Size to Adapt to Your Workpiece Dimension: Includes table extension system, expandable by 400 or 800 mm per side, up to 1600 mm total.

- Minimal Space Requirement, Mobile in Every Workshop: Space-saving design with optional rolling carriage for mobility.

Details

- Strong Motors – Perfect Power Transmission: The power transmission of the motor power to the saw arbour is achieved using large dimensioned Poly-V belts and counter surface. The surface area increased through the V shape of the drive belt on the pulley ensures an almost perfect transmission of power from the motor to the saw arbour.

- Stable-Compact-Precise, the Hammer Saw Aggregate: The Hammer saw aggregate impresses with smoothness, precision, and extreme user-friendliness. The large cutting height of 103 mm leaves nothing to be desired. Saw blades with up to 315 mm diameter can be lowered completely below the level of the saw table. The saw blade is simple to access and can be changed with ease. The blade can be tilted to any position between 90° and 45° and guarantees precise mitre cuts. End stops at the 90° and 45° position ensure the exact positioning of the settings; a large dimensioned scale makes the exact setting and reading of the value easy.

- Scoring Unit for Laminated Workpieces: The scoring unit ensures chip-free cuts in laminated workpieces. The cutting width of the two-part scoring blade can be adjusted accurately to the tooth width of the main saw blade using a ring set. The drive of the scoring blade is done mechanically, with it rotating in the opposite direction to the main saw blade.

- Grooving, Slot and Tenoning with the Saw: Every Hammer panel saw can be equipped with a preparation for the use of specialised dado tooling. The dado tool can be fitted to the saw arbour and makes it possible to make various width grooves, tenons, and slots of between 8 and 19.5 mm in width.

- The Industrial Rip Fence: The industrial rip fence runs on a round bar. This ensures a smooth operation, ease of use, and maximum rigidity. With the micro-adjustment, you can easily adjust the fence to the required position with very high precision.

- The Aluminium Sliding Table: The aluminium sliding table gives the precision from the first cut. Guaranteed Hammer stability and precision: the strong ribbed, milled, and anodised aluminium hollow-chamber profile of the sliding table in combination with the high-quality guiding system ensures maximum accuracy and precision!

- Crosscut and Miter Cuts: Adjustable to any position between +45° and –45°, the crosscut fence ensures precise angled and mitre cuts. A scale integrated into the aluminium sliding table makes it easy to set precisely. The end stop for the 90° position guarantees absolute precision with repeat settings. The scale on the 900 mm long aluminium crosscut fence is angled towards the operator and makes it easy to comfortably read the exact setting. In combination with the crosscut stop with integrated magnifying glass, highly precise settings and as such absolutely exact results are guaranteed.

- Table Size to Adapt to Your Workpiece Dimension: Processing long and heavy workpieces without assistance - no problem with a Hammer! The Hammer table extension system has proven itself thousandfold, the world over. In just a few steps and without tools, the table extensions can be mounted to every Hammer machine. The surface can be extended by 400 or 800 mm on each side of the working table, which means that it is possible to increase your table length by up to 1600 mm!

- Minimal Space Requirement, Mobile in Every Workshop: Hammer woodworking machines are an absolute spatial wonder. The efficient machine design of a Hammer means that space can be found in even the smallest of workshops. As an option, a rolling carriage can be fitted to every Hammer, offering mobility and freeing up additional space.

Technical Specifications

| Category | Details |

|---|---|

| Electrics |

|

| Saw Unit |

|

| Anodised Format Sliding Table |

|

| Outrigger Tables and Crosscut Fences |

|

| Weight |

|

| Accessories |

|