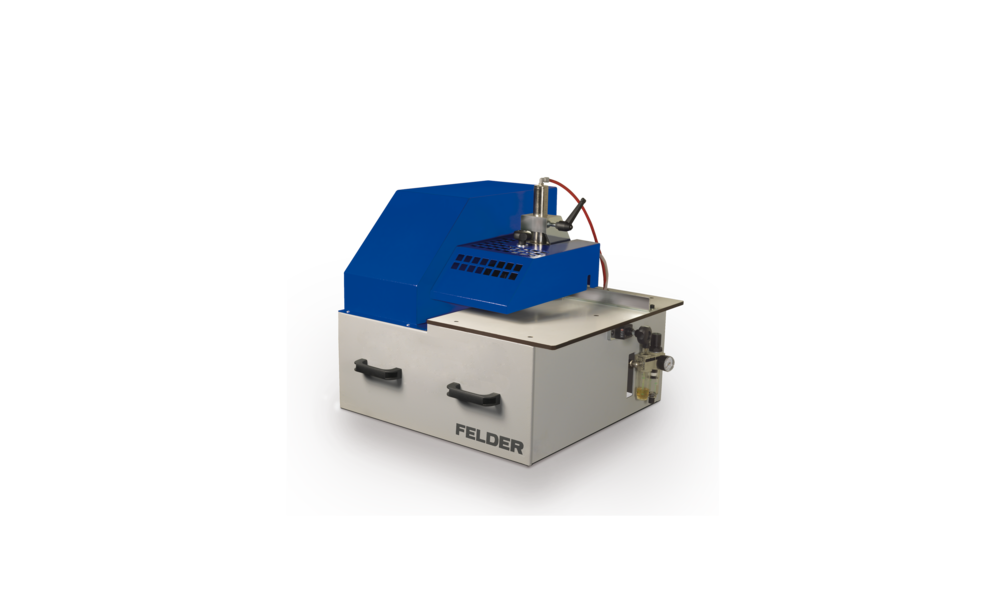

Felder | ERM 1050 Corner Rounding Machine

by Felder Group

Original price

$50,000.00

-

Original price

$50,000.00

Original price

$50,000.00

$50,000.00

-

$50,000.00

Current price

$50,000.00

Fast and Precise Corner Rounding for Small Workshops

This little helper should be in every small workshop! 1 - 2 - 3 – finished rounded work-piece corners now only in 3 seconds! You can now round ABS and PVC corner edges in less than 3 seconds. Simply place the workpiece into the unit, start the machine and the corner is rounded. It really is that simple and precise. The new Felder corner rounding unit offers professional processing of all types of workpiece edges including edges of post- or soft-formed materials.

- 1 - 2 - 3 – finished rounded work-piece corners now only in 3 seconds!

- You can now round ABS and PVC corner edges in less than 3 seconds

- Simply place the workpiece into the unit, start the machine and the corner is rounded

- It really is that simple and precise

- The new Felder corner rounding unit offers professional processing of all types of workpiece edges including edges of post- or soft-formed materials

Key Features

Highlights

- Ultra-Fast Corner Rounding: Completes the rounding of workpiece corners in less than 3 seconds, a significant time-saver for small workshops. This efficiency is achieved through a straightforward process where the operator places the workpiece, activates the machine, and obtains a finished edge, streamlining production workflows.

- Pneumatic Operation: Runs entirely on air pressure with a minimum requirement of 6.5 Bar, eliminating the need for electrical power. This pneumatic control drives the router motor, router movements, and workpiece clamp, ensuring a reliable and maintenance-friendly operation suitable for various workshop environments.

- Workpiece Holder/Pneumatic Clamp: Features a pneumatic clamp that securely holds the workpiece during processing, preventing slippage and guaranteeing optimum results. This is particularly beneficial when handling larger workpieces, enhancing stability and precision throughout the rounding process.

Details

- Quick and Accurate Setup: The machine’s setup is highly efficient, with workpiece height adjustments displayed on a digital readout for quick and accurate configuration. Controlled by a foot pedal, this design leaves the operator’s hands free to support the workpiece, improving safety and ease of use while its space-saving design boosts workshop productivity.

- Versatile Material Processing: Offers professional processing of a wide range of edge types, including ABS, PVC, and solid strips with thicknesses between 0.4 and 3.0 mm. Additionally, it can handle post- or soft-forming workpieces, providing flexibility for diverse woodworking projects and accommodating various material demands in small-scale operations.

- Router Bit Flexibility: Comes standard with two router bits featuring 2 mm and 3 mm radii, enhancing the machine’s adaptability. The use of different router bits increases the range of materials that can be processed, and the support bed ensures perfect workpiece handling, allowing for customized edge finishing based on specific project requirements.

- Compact and Efficient Design: Tailored for small workshops, the ERM 1050’s compact footprint makes it an ideal addition where space is at a premium. Its pneumatic operation and foot pedal control contribute to a simple, space-saving layout that maximizes productivity without requiring extensive floor space.

- Durability and Precision: Built with Felder’s 60 years of engineering expertise, the machine ensures long-term reliability and precision. The pneumatic clamp and router system, combined with high-quality components, deliver consistent results, making it a dependable tool for professional use in constrained settings.

- Optional Enhancements: While not detailed as standard, the design’s modularity suggests potential for custom configurations, such as additional router bits or specialized clamps. Web information (e.g., from felder-group.com) indicates compatibility with various edge thicknesses and post-forming materials, which could be explored based on specific workshop needs, though no specific options are listed in the provided text.

Technical Specifications

| Category | Details |

|---|---|

| Corner Rounding Unit |

|

| General |

|