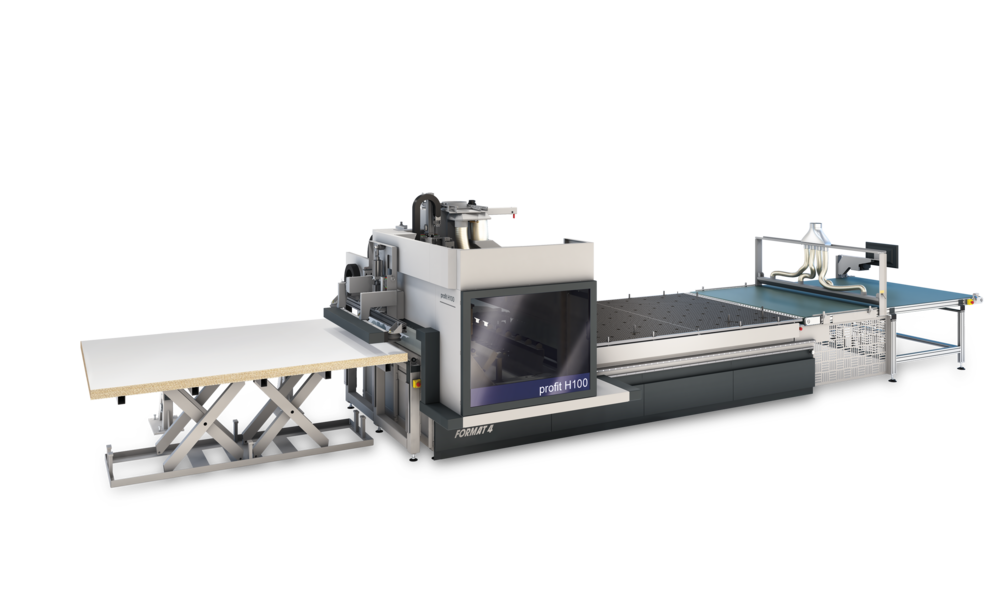

Format4 | profit H100 Nesting CNC Machining Center

Future-Proof CNC Nesting for Maximum Productivity

The panel cutting, drilling and milling centre for future-proof carpentry and joiner's workshops. Entire custom-made furniture with all holes, grooves and connections are produced in one single operation. The latest nesting technologies ensure the highest possible material and time savings. The profit H100 can be extended to full automation with different loading and unloading solutions, thus achieving maximum productivity.

Four sizes (16.38, 22.32, 22.43 & 22.61) are available with integrated SMART ZONING vacuum management, high-end automation levels, above-average drill heads, new safety concepts and much more. For the unrestricted use of the spindle, a recessed series of fence rows is available. A large Z passage size of 200 mm offers flexible machining of high workpieces.

With the standard tool changer and optionally available moving rotary tool changer as well as the pick-up space for a large saw blade, a total number of up to 35 tool places are available. The automatic pre-labelling on the loading table minimizes sources of error and at the same time reduces the processing times.

With the performance package, the CNC control makes the highest industry standard possible. Different optimisation levels ensure shorter process times, different milling results and increased comfort in CNC machining. » Automation solutions

Key Features

Highlights

- Advanced Nesting Technology: Enables complete custom furniture production—including cutting, drilling, and milling—in a single operation, leveraging the latest nesting technologies for maximum material and time savings, ideal for future-proof carpentry and joinery workshops.

- Flexible Size Options with Smart Zoning: Available in four sizes (16.38, 22.32, 22.43, and 22.61), each featuring integrated SMART ZONING vacuum management for quick processing of multiple panel formats, enhancing adaptability and efficiency across various workshop sizes.

- Powerful Main Spindle with Extensive Tool Capacity: Equipped with a spindle offering 10, 12, or 15 kW power (up to 24,000 rpm), supported by a standard tool changer and an optional moving rotary tool changer, providing up to 35 tool places for versatile machining tasks.

Details

- Drilling Head Configuration Options: Offers flexibility with a choice of drilling heads—either vertical spindles or a combination with a grooving saw for vertical and horizontal processing. The inverter-controlled motor reaches up to 7,500 rpm, covering the entire working field for efficient drilling.

- Large Z Passage Size: Provides a 200 mm Z passage, allowing flexible machining of high workpieces, supported by a recessed series of fence rows for unrestricted spindle use, enhancing the machine’s capability for diverse material heights.

- Automatic Pre-Labeling System: Minimizes errors and reduces processing times with pre-labeling on the loading table, ensuring accurate identification and streamlining workflow, especially beneficial in automated setups.

- F4®Integrate Software: Delivers a state-of-the-art interface with a tool library (F4Toolbox), programming section (F4Create with CAD), and machine control (F4Operate) on one screen. Based on G-Code, it supports external programs, offering intuitive and efficient operation.

- Position-Controlled Extraction Connection: Automatically adjusts full extraction capacity between the drilling head and main spindle based on usage, with an extraction bell optimizing suction results and reducing required extraction volume for a cleaner workspace.

- Phenolic Resin Table with Vacuum Pods: Features a phenolic resin table that supports vacuum block pods, increasing variability and ensuring a non-corrosive, heat- and cold-resistant surface for precise workpiece positioning.

- Automation and Lifting Table: Extendable with various loading and unloading solutions, including a lifting table that positions panel stacks to the appropriate working height, aligning materials synchronously for enhanced productivity.

- Performance Package Enhancements: Includes a Siemens control system with up to 30% faster axis speeds, 80% optimized positioning and rotation speeds, multitouch functionality, smooth tool movements via jerk control, and reduced vibration for superior surface finishes.

- Attachments and Accessories: Offers optional features like automatic labeling units, under-table and upper-table extraction, and a linear tool changer with HSK adaptors protected from dust and chips. Web context suggests compatibility with advanced automation (e.g., loading/unloading systems), reflecting Format4’s modular design.

- Durability and Precision: Built with solid design and premium Austrian components, the profit H100 ensures uncompromised productivity, supported by a perfect service package and networked workshop capabilities.

Technical Specifications

| Category | Details |

|---|---|

| Machining Unit |

|

| General |

|