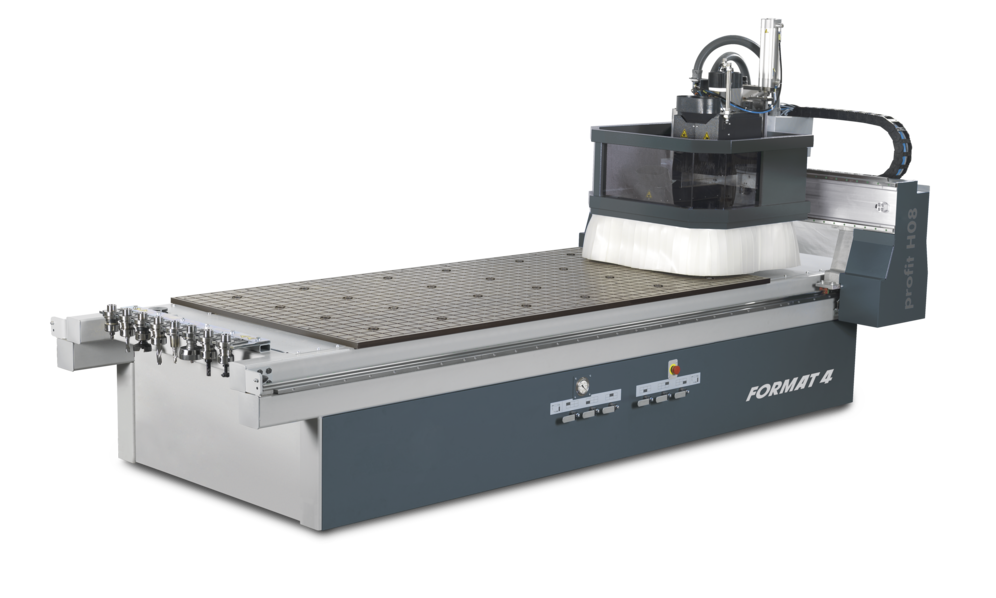

Format4 | profit H08 Nesting CNC Machine Center

by Felder Group

Original price

$50,000.00

-

Original price

$50,000.00

Original price

$50,000.00

$50,000.00

-

$50,000.00

Current price

$50,000.00

Space-Saving CNC Nesting for Maximum Efficiency

Specially developed for universal application, the profitable Format4 CNC all-rounder impresses with the highest precision and outstanding productivity when processing a wide range of materials. The profit H08 from Format-4 is the CNC-machining center for professional nesting applications, and requires only minimal space. Offering maximum flexibility and efficiency, even in its basic version with 8 or 11 tool slots, it is a convincing choice. The main spindle with a very powerful 12 kW motor ensures perfect, tear-free results. The main spindle is completed by an optional drilling head with 8 spindles.

- Complete processing of cabinets in just one operation

- Material-saving panel processing with nesting optimization

- Vacuum system with maximum holding force – up to 750 m³/h

- Automatic measuring system of the tool length with accuracy to a hundredth of a millimeter

- Automatic central lubrication for optimal performance and longevity

- High-precision drill head (optional) with 8 vertical drill bits

- Automatic tool change with HSK F63 taper

- Torsion-resistant machine frame made of steel

- Choose between 6 or 8 vacuum zones for optimal holding force

- Optional high flow nesting table

- Portal design with 'Gantry' drive for fast, precise, low-maintenance operation

- Stop cylinder for maximum precision and repeatable positioning

- Compact design fits into any workshop

Key Features

Highlights

- Compact and Efficient Design: With a space-saving footprint of 18.37 ft x 12.43 ft (5600 mm x 3790 mm) for the 13.25 model or 20.34 ft x 13.41 ft (6200 mm x 4090 mm) for the 16.31 model, this machine fits into any workshop while delivering complete cabinet processing in a single operation, optimizing space and productivity.

- Powerful 12 kW Main Spindle: Ensures perfect, tear-free results with a 10 kW router spindle option (24,000 rpm), controlled via an inverter and attached to the drill head module, offering robust performance for a wide range of materials.

- Automatic Tool Change with HSK F63 Taper: Features a powerful torque transmission system with automatic tool clamping, checked by sensors and cleaned pneumatically, enabling reliable and quick handling of demanding machining operations.

Details

- Working Area and Speed: Offers a fully machinable working area of 4.10 x 8.20 ft (1250 x 2500 mm) for the 13.25 model or 5.01 x 10.13 ft (1530 x 3090 mm) for the 16.31 model, with an X-axis speed of 25 m/min (optional 50 m/min) and Y/Z-axis speeds of 25–15 m/min, ensuring efficient processing across standard panel sizes.

- Vacuum System with Smart Zoning: Provides a maximum holding force with up to 750 m³/h, utilizing 6 or 8 vacuum zones (manually or automatically controllable). The phenolic table, resistant to heat and cold, ensures accuracy, with an optional high-flow nesting table for enhanced performance.

- Automatic Tool Length Measuring System: Measures tool length with an accuracy of one-hundredth of a millimeter, storing data in the tool database to eliminate operator errors, enhancing precision and setup efficiency.

- Automatic Central Lubrication: Continuously supplies lubrication to critical components of the X, Y, and Z axes via a time-controlled pneumatic system, reducing wear, preventing downtime, and minimizing manual maintenance efforts.

- High-Precision Drill Head (Optional): Features 8 vertical drill bits with integrated dust extraction, accelerating the drilling process and extending the main spindle’s lifespan, available as an upgrade for enhanced versatility.

- Torsion-Resistant Steel Frame: Constructed from solid, torsion-resistant steel, this frame guarantees maximum stability and durability during intensive continuous operation, supporting the machine’s high-precision performance.

- Portal Design with 'Gantry' Drive: The dual-sided drive ensures fast, precise, and low-maintenance machining operations, with a stop cylinder providing repeatable positioning for first-class results across applications.

- Automatic Adjustment of Extraction Hood: Adjusts to workpiece height, supporting a maximum router cutter diameter of 7.87" (200 mm), offering wide-ranging material processing flexibility while reducing dust and noise emissions.

- Attachments and Accessories: Includes optional features like additional vacuum zones, a high-flow nesting table, and a stop cylinder. Web context suggests compatibility with advanced aggregates (e.g., 5-axis units, label printers), reflecting Format4’s modular design, though not detailed here.

- Durability and Precision: Built with solid design and premium Austrian components, the profit H08 ensures uncompromised productivity, supported by a perfect service package and automation solutions, making it a reliable investment for professional nesting applications.

Technical Specifications

| Category | Details |

|---|---|

| Machining Unit |

|

| General |

|