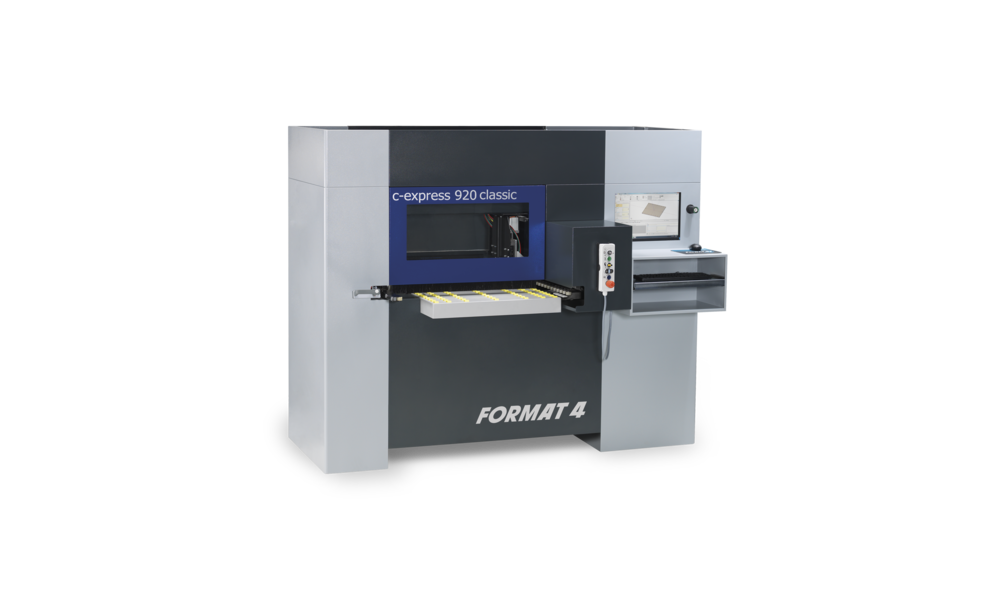

Format4 | c-express 920 classic CNC Machine Center

Compact Precision CNC Milling for Small Workshops

The new c-express 920 classic Format4 CNC drilling and milling centre, carries out all repeat drill and simple milling work efficiently and precise, all in record time. Developed with the smaller workshops in mind, the c-express 920 classic offers a sensational price/performance ratio. Uncompromised development at Felder ensures you profitable CNC productivity. At the touch of a button, repeat drilling work programs can be loaded and reused. This ensures that CNC controlled cabinet production is a profitable option for every workshop, regardless of space constraints. Highlights: Compact CNC processing in just 3.4 m² High precision 17 spindle drilling head for maximum flexibility Horizontal processing of the workpiece ensures a constant zero point Simple programming without the need to take the workpiece thickness into consideration Grooving saw unit as standard for the processing of back panels or contruction connections Modern laser measuring technology ensures highest measuring precision

- Compact CNC processing in just 3.4 m²

- High precision 17 spindle drilling head for maximum flexibility

- Horizontal processing of the workpiece ensures a constant zero point

- Simple programming without the need to take the workpiece thickness into consideration

- Grooving saw unit as standard for the processing of back panels or contruction connections

- Modern laser measuring technology ensures highest measuring precision

Key Features

Highlights

- Compact Footprint with Efficient Processing: Occupies just 3.4 m², making it an ideal space-saving solution for smaller workshops. This compact design allows for high-precision CNC drilling and milling in record time, enhancing productivity without requiring extensive floor space.

- High-Precision DH17 8H 1S Drilling Head: Equipped with 9 vertical spindles, 8 horizontal spindles, and 1 slot cutter on the X-axis, this 17-spindle head provides maximum flexibility for a wide range of drilling tasks, ensuring versatile and accurate machining.

- Intuitive Programming and Control: Features a graphical user interface with the "Woodflash" programming software and a 19" LCD color monitor, offering simple programming without needing to account for workpiece thickness. Optional "Flash 3D" cabinet programming software further streamlines customer order processing.

Details

- Working Area Flexibility: Offers a minimum working area of 280 mm (X) x 180–70 mm (Y) x 10 mm (Z) and a maximum of 3000 mm (X) x 920 mm (Y) x 50 mm (Z). An extra attachment for narrower workpieces (70–180 mm width) ensures exact processing, while the pressure device guarantees consistent depth for wide or thin workpieces.

- Horizontal Workpiece Transport System: Ensures smooth and accurate positioning of workpieces up to 30 kg, processed from below by the aggregates. The side-positioned fence allows width adjustments up to 920 mm, with dual-side support and guidance for highly precise results, preventing movement or burning.

- Shaper Spindle with Milling Aggregate: An optional milling unit, clamped with an ER32 chuck and manually changeable, supports routing cutouts, pockets, grooves, and rebates. It facilitates 3-sided reference cuts and milling forms within the workpiece, requiring right-angle positioning for optimal performance.

- Modern Laser Measuring Technology: Utilizes a laser and encoder system to measure workpiece length with high precision, critical for cabinet construction connections without overhang. This advanced measuring technology enhances accuracy and repeatability.

- Pressure and Hand Terminal Adjustments: Offers maximum adjustable pressure up to 100 kg for optimal results on sensitive surfaces, controlled via a freely positionable hand terminal that simplifies the working process by being available on demand.

- Rear Unloading Capability: Allows programming to feed the workpiece to the rear when finished, enabling integration into a production line. The unloading direction is easily selected via a switch, enhancing workflow flexibility.

- Optional Attachments and Enhancements: Includes optional additional tables for infeed and outfeed sides to support longer workpieces. Web information suggests compatibility with advanced features like automated tool changers or additional clamping systems, though not detailed here, reflecting Format4’s modular design approach.

- Durability and Precision: Built with solid design and premium components from Austria, the c-express 920 classic ensures uncompromised productivity and engineering precision, supported by a perfect service package, automation solutions, and networked workshop capabilities.

Technical Specifications

| Category | Details |

|---|---|

| Machining Unit |

|

| General |

|