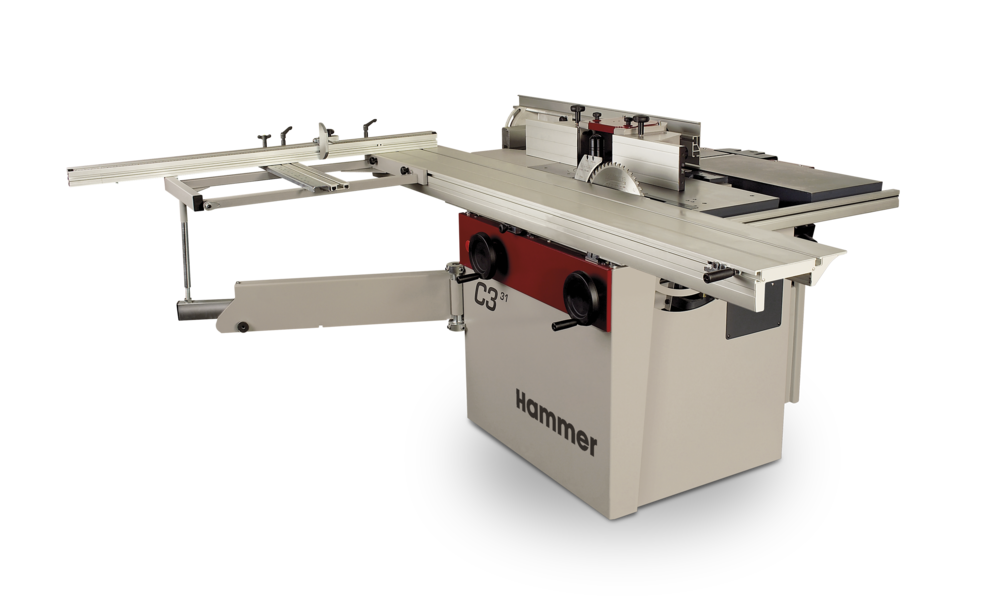

Hammer | C3 31 comfort Combination Machine

by Felder Group

Original price

$50,000.00

-

Original price

$50,000.00

Original price

$50,000.00

$50,000.00

-

$50,000.00

Current price

$50,000.00

Your Workshop on Only 1.5 m² Extremely Compact

The Hammer C3 31 comfort Combination Machine enhances woodworking versatility with a 12 13/64" planing width and an extended 80 45/64" cutting length. Integrating planing, cutting, moulding, and optional mortising for solid wood and panel materials, it features an outrigger table and dual folding planer tables for precision and quick changeovers in a compact 1.5 m² footprint.

Key Features

Highlights

- 3 Knife Quick-Change Cutterblock System: Enables rapid blade changes without adjustments for excellent planed surfaces.

- X-Roll Aluminum Sliding Table: Ribbed, anodised profile ensures precision cutting with a 10-year warranty.

- Silent-Power® Spiral Cutterblock: Optional feature reduces noise by 50%, extends blade life up to 20 times, and ensures tear-free planing.

Details

- Solid Planer Tables: Ribbed cast iron tables match 12 13/64" planing width for precise workpiece guidance.

- Quick Depth of Cut Adjustment: Large handle allows up to 4 mm cut depth adjustments without locks.

- Dual Opening Planer Tables: Space-saving, ergonomic design with simultaneous table tilting and automatic locking at 0°.

- Perfect Extraction Technology: Optimized dust extraction hood ensures a clean working surface.

- Planer Fence: Aluminum fence tilts 90°–45° with fine-adjustable stops for precise joining and bevelling.

- Table Extension System: Tool-free extensions up to 62 63/64" (400 or 800 mm per side) for large workpieces.

- Maximum Thicknessing Height: 8 55/64" (225 mm) supports large workpieces, with optional digital handwheel for 0.1 mm precision.

- Stable Saw Aggregate: Supports 250–315 mm blades with 4 1/16" cutting height, easily adjustable.

- Rip Fence: Adjustable 0–600 mm with flat position for thin workpieces.

- Spindle Moulder Unit: 30 mm spindle with four speeds (3,000/6,000/8,000/10,000 rpm) and forward/reverse run for safety.

- Spindle Fence: Supports tools up to 8 21/32" diameter, with –5 to +25 mm depth adjustment and 120 mm extraction connection.

- MF Spindle Quick-Change System: Allows rapid spindle swaps (optional).

- Grooving, Slot, and Tenoning: Optional dado tooling for 8–19.5 mm wide grooves and slots.

- Scoring Unit: Optional mechanically driven unit (Ø 80 mm) for chip-free cuts in laminated workpieces.

- Saw Blade Tilt 90°–45°: Ensures precise mitre cuts with end stops at 90° and 45°.

- Outrigger Table: 1100 mm table for precise panel and cross cuts.

- Crosscut Fence: 51 3/16" fence for +45° to –45° mitre cuts with precise stops.

- Mortising Unit: Optional attachment for drilling and chiselling tasks.

- Minimal Space Requirement: Efficient design with optional rolling carriage for mobility.

Technical Specifications

| Category | Details |

|---|---|

| Electrics |

|

| Planing Unit and Cutterblock |

|

| Planer and Feed Drive |

|

| Saw Unit |

|

| Spindle Moulder Unit and Spindle Fence |

|

| Anodised Sliding Table |

|

| Outrigger Tables and Crosscut Fences |

|

| Mortising Unit |

|

| General |

|

| Accessories |

|