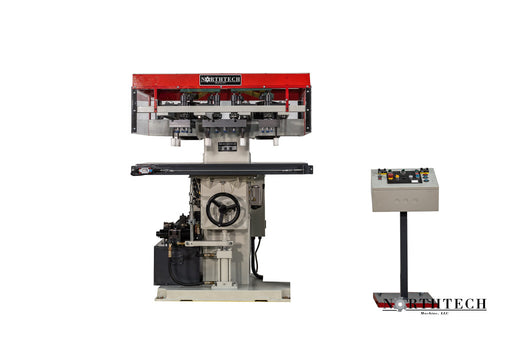

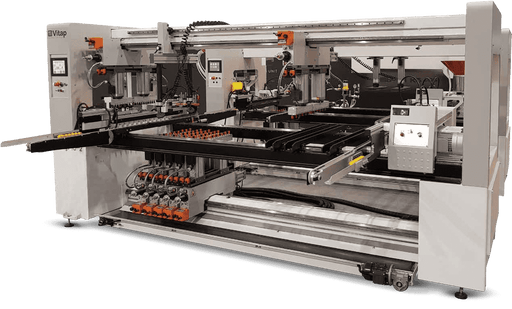

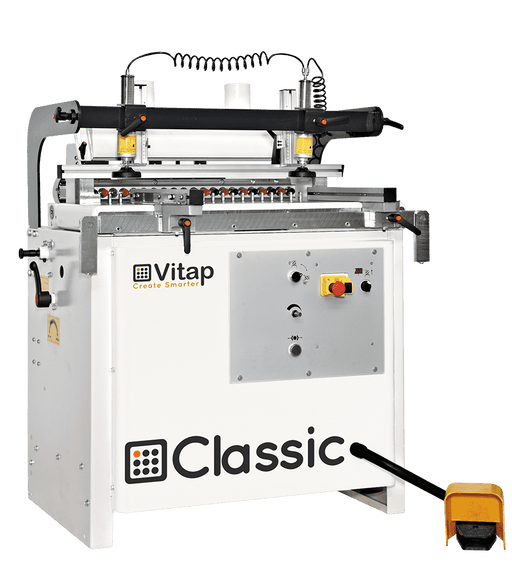

A boring machine for industrial woodworking is a specialized tool designed to drill precise and accurate holes in wood, typically for joinery, cabinetry, and furniture making. Boring machines are known for their ability to create holes with exceptional precision, depth, and consistency, which is crucial for tasks like attaching hinges, assembling joints, and joining various wooden components. These machines come in various configurations, including line boring machines, doweling machines, and hinge boring machines, each tailored to specific woodworking tasks. Boring machines streamline the hole-making process, ensuring that holes are perfectly aligned, sized, and positioned, ultimately contributing to the quality and efficiency of woodworking projects.

Key Features of Boring Machines:

Boring machines offer a range of features to enhance their functionality:

- Adjustable Depth and Positioning: Many models allow for precise depth and horizontal/vertical positioning adjustments.

- Multiple Spindles: Some boring machines have multiple spindles, enabling the simultaneous drilling of multiple holes.

- Drill Bits and Chucks: The ability to use a variety of drill bits and chucks for different hole sizes and styles.

- Integrated Dust Collection: Effective dust collection systems to maintain a clean workspace.

Applications of Boring Machines:

Boring machines find applications in various woodworking tasks, including:

- Cabinetry: Boring machines are used for creating holes for cabinet hardware, like hinges, knobs, and pulls.

- Furniture Making: In furniture production, boring machines are essential for creating joints, dowel connections, and other assemblies.

- Joinery: They play a crucial role in creating mortise and tenon joints, which are common in traditional woodworking.

Benefits of Using Boring Machines:

The advantages of incorporating boring machines into woodworking operations are substantial:

- Precision: Boring machines deliver highly precise and consistent hole drilling, reducing the need for manual adjustments.

- Efficiency: These machines expedite the hole-making process, saving time and improving production efficiency.

- Quality Improvement: Boring machines enhance the quality of woodworking projects by ensuring that holes are perfectly aligned and sized.

Choosing the Right Boring Machine:

Selecting the appropriate boring machine depends on specific project requirements:

- Hole Type: Consider the type of holes you need to drill and select a machine tailored to those specifications.

- Number of Spindles: Evaluate whether you require a single-spindle or multi-spindle machine based on your drilling needs.

- Adjustability: Look for models with precise depth and positioning adjustments for versatility.

- Dust Collection: Machines with effective dust collection systems contribute to a cleaner and safer workspace.

In conclusion, boring machines for industrial woodworking are indispensable tools for creating precise and accurate holes in wood, essential for joinery, cabinetry, and furniture making. Understanding their key features, applications, benefits, and considerations for selecting the right model is essential for optimizing woodworking processes and achieving high-quality results. Boring machines enhance the efficiency and precision of hole drilling, making them invaluable assets in the woodworking industry.